There are a few important points here which I learn’t from the process.

Scarfing.

I used the jig described in the One Ocean Kayaking building manual. It worked but my implementation of the jig wasn’t that great. In retrospect I think I might in future either do it by hand using a sharp plane, or use a router jig I’ve seen on the Kayak Forum.

Holding onto a circular saw and ensuring it cuts cleanly and evenly across the ply requires a fair bit of attention and a good horizontal guide with a clean, straight edge. The first piece I used was too thin and had a slight waiver in the middle. Better to make it nice and wide so it remains a true straight edge.

The ply sheets are thin with external veneers and an internal core; the saw is rough, so use a bit of waste material as the bottom and top layers. I ended up with the top and bottom sheets having some tatty edges (because of course I didn’t use the waste material top and bottom).

Clamp or weigh down the center of the sheets otherwise the middle has a habit of lifting.

Finally, check before you’ve finshed that the scarf is accurately square to the long edge of ply. Use a large builders square. If I had I would’ve seen I had a waiver in the middle of my scarfs.

Scarf Gluing

This would’ve been a whole lot easier if I didn’t have that waiver in the scarf!

Having said that, the output hasn’t been that bad. There was some badly overlapping ply, and I really should have taken more time with the weighting down of the joint, and actually, in retrospect I went too light with the epoxy, but in the end it appears to have worked fine.

Just one note on the use of the epoxy. This was the first time I’d used the epoxy and if there’s one lesson with doing anything new – it’s give yourself time and opportunity to learn from your errors. I’ve tried a few different methods of application in the last 2 weeks and my current favourite is the nylon brush topped foam pads that are sold in the hardware stores as speed brushes. I can buy the pads for just a few dollars and they stick onto a plastic holder which, at least for me, is easier to work with than a roller.

I think the best approach is to mix up some epoxy, run a quick line of it up and down the scarf edges to allow it to soak in; then add an adhesive filler, give it a swirl and apply it to the edges before joining. This will help fill voids better than just epoxy itself.

Cutting the Panels

First discovery: positioning the paper patterns on the ply with spray on glue was a breeze. I was worried that I’d permanently stick the patterns on but it was surprisingly easy to apply a thin coat that would allow me to reposition a pattern. Having said that, I did end up using a couple of different spray glue brands. The 3M glue seemed to be far better to use.

I also used a string line for the main pattern that included the hull pieces. This is such a long paper pattern that I wanted to be sure that a center line drawn on the pattern actually ran straight down the table. Getting this wrong would be annoying as you’re cutting through two ply panels not just one.

I drilled the tie wire holes next and put little bits of wire in the lot of them to keep the panels from moving; then just for overkill I decided I’d hot glue round the edges of the two panels. I used a sharp hobby knife to cut round the pattern edges – surprisingly easy to do. Then I used a jigsaw to cut out each piece. The jig saw did a good job (I think) but the best method appeared to be to stay a mm or two away and use a block plane or sanding block to finish. That gave a very good finish. Just to give myself time to improve I purposefully cut the stations first.

Since cutting the main panels I’ve actually moved to using a fine point panel saw. It’s just less noisy, less dusty and more accurate for the straighter lines.

Lifting the cut pieces was alarming, They wobble a lot and by experimenting with offcuts I could tell the scarf joints could break at the point the ply starts to thin. There was often no epoxy at that point and when combined with a thinning (or complete lack) of external veneer, the ply was substantially weakened. My advice: don’t go too light on the epoxy round the scarf joint, and make sure in the positioning of the pieces that the inner ply layer isn’t left substantially exposed anywhere along the joint.

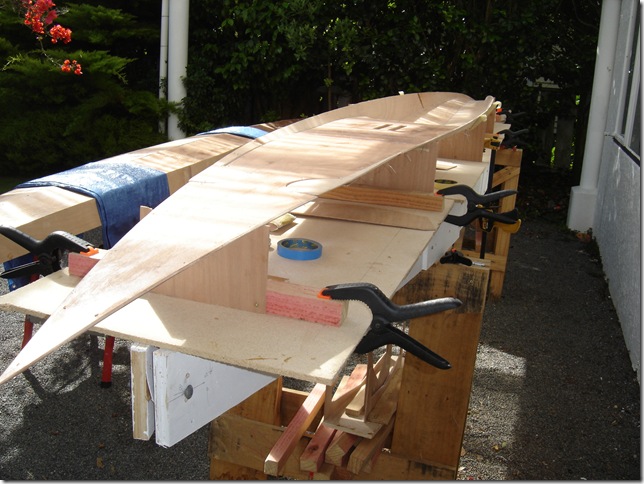

If you do get a dodgy joint just try a wood backing block. In the case of the photograph below I’d been a bit aggressive and planning away some badly overlapping ply on a scarf. The result was a weak point so I then thinned a piece of scrap ply down and glued that onto the joint. I later sanded this down so just a thin veneer was left covering the low points. It appears to have fixed my problem nicely. (Note that I decided to put a thin epoxy coat on panels but at the time I took the photo I hadn’t epoxied under the clamp.)